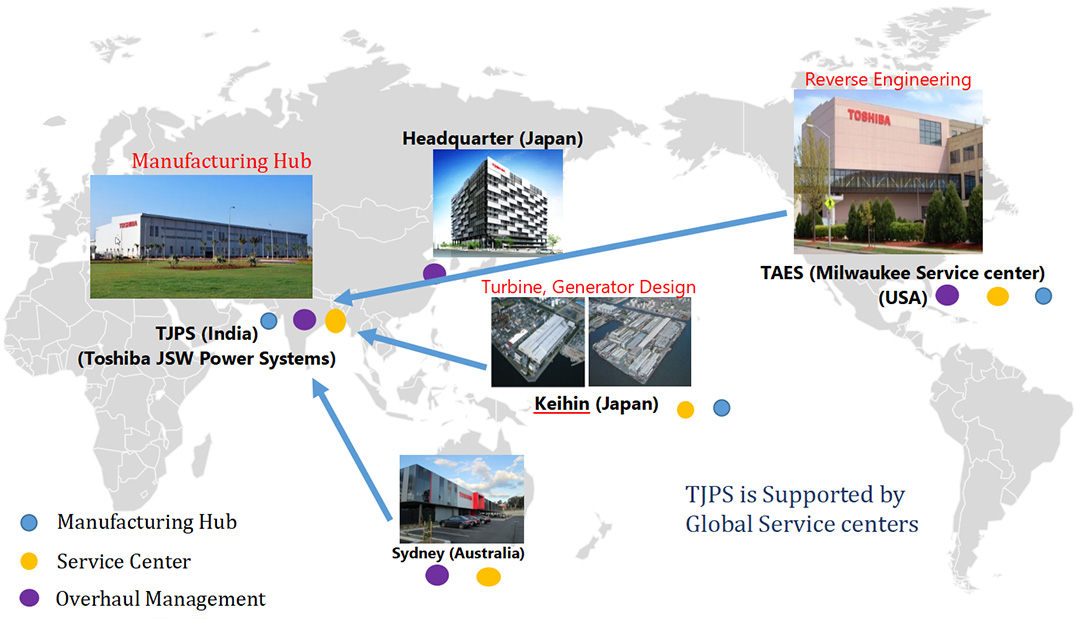

TOSHIBA JSW AND TOSHIBA GLOBAL FOOTPRINTS FOR SERVICES

Overhaul Management

MAINTENANCE SERVICES FOR STEAM TURBINE

- Open, Clean, Close Services (Overhauling)

- Repair

- Replace Parts

- Parts Supply

- Engineering Services

OPEN, CLEAN, CLOSE SERVICES (OVERHAUL)

- Overhaul Planning

- Site Visit for Preparation (3 - 6 months ahead of overhaul)

- Mobilization of needful (T/A, Manpower, Tools, Instruments, Consumables, etc.)

- Disassembly

- Cleaning

- Inspection (VT / DT / NDE)

- Repair (*If necessary)

- Replace Parts (*If necessary)

- Re-assembly

- Re-commissioning

- Report Presentation

Repair / Replacement is decided based on inspection results and standardized criteria derived from the abundant field experiences and extensive knowledge of turbine design.

Repair

- Weld Repair of LP Inner Casing Horizontal Joint Surface (Erosion) (at site)

- Weld Repair of Gland Packing Casing Horizontal Joint Surface (Erosion) (at site)

- Weld Repair of Eroded Nozzle Partitions (at site)

- Machining of Dishing of Nozzle Diaphragm (at Chennai factory)

- Re-Babbiting of Damaged Bearing Metal (at Chennai factory)

- Machining of Damaged Rotor Journal (at site)

- Dressing of Damaged Blade (at site)

- Rotor Balancing (Low/High speed balancing) (Low speed balancing at site, high speed balancing at Chennai factory)

- Crack repair of HP turbine casing (at Chennai factory)

REPLACE

- Blades

- Rotor

- Nozzle

- Diaphragm

- Nozzle Box

- Packing Casing

- Bearing

- Seal ring

- Packing Ring

- Tip fin

PARTS SUPPLY - CONCEPT OF CHENNAI FACTORY

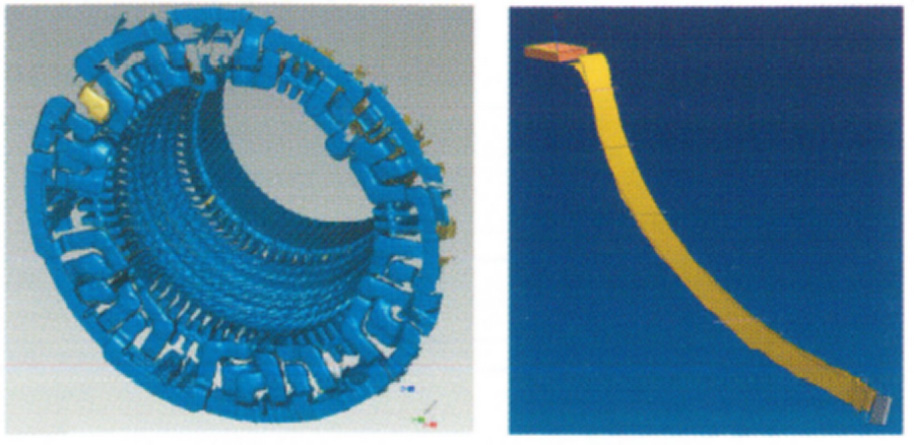

Toshiba JSW Chennai factory has full-scale manufacturing of all parts and components of Turbines and Generators, completely manufactured in-house.

Turbine Rotors

Blades

MSV/CV

Nozzles

Turbine Casings

Generator Stator & Rotor

Parts Supply

- Blades (O-OEM design / Toshiba design)

- Diaphragms ( for O-OEM design / Toshiba design)

- Gasket / Packing

- Miscellaneous small parts (lock plate/bolt/nut /pin/shim/key, etc.)

- Tip fins

- Seal ring

- Casing stud / nut

- Bearing

- Packing ring (O-OEM design / Toshiba design)

- Others

Maintenance services of Generators

i. Overhauling of Generator

- De-coupling of LP - Gen

- Hydrogen Purge out and stator cooling water draining

- Leak test of Generator frame

- Leak test of coil (In-leak test, pressure and Vacuum decay test

- Hydrogen cooler removal and inspection

- Rotor Thread-out

- Inspection and Testing of stator, Rotor and other components

- Repair / Replacement of parts as desired

- Rotor thread in and re-assembly

- Lube oil, Seal oil system normalisation

- Generator frame leak test

- Stator cooling water system normalisation

ii. Rotor Maintenance / Modernization Services

- Complete rewinds-new or refurbished copper winding

- Retaining ring machining and replacement

- Winding and insulation inspection and repairs

- Main leads inspection, repairs and replacement

- Diagnostic inspection and evaluation

- Collector ring repairs and replacement

- Hydrogen seal repairs and replacement

- Bearing journal machining and repairs

- Cooling fan and other parts manufacturing

- Robotic inspection of the Generator Rotor without rotor thread out (by TESS)

iii. Stator Maintenance / Modernization Services

- Complete rewinds, including core restacking, if required

- Winding and insulation inspection and repairs

- Core inspection, repairs and tightening

- Frame and mechanical inspection and repairs

- Re-wedging

- End winding repairs and upgrades

iv. Rotor Testing & Inspection Services

- Electrical testing:

- Insulation resistance and polarization index

- DC resistance

- AC impedance and pole-to-pole voltage drop testing

- Pole Balance Test

- RSO - Repetitive Surge Oscilloscope testing

- Collector lead stud seal leak testing

- Beneath retaining ring visual inspection with video-scope

- Retaining ring inspection and testing (rings on or rings off)

- Visual inspection and assessment

- Bearing journal and collector ring dimensional checks

v. Maintenance services of Generator - Solutions for Generator problems

- Stator

- End winding vibration

- Core melt

- Stator winding water leak

- Stator winding plugging

- Rotor

- Inter turn short

- Rotor coil overheating

- Copper dusting

- Cracking of pole to pole connector and main lead

- Shaft crack of retaining ring shrink fit portion

- SCC of coil retaining ring

- Rotor vibration

- Slot dovetail crack

- Fan Blades / Bolts crack

MAINTENANCE SERVICES OF STEAM VALVES (MSV, CV, CRV, OLV)

Valve Repair & Upgrade Programs

- Complete de-scaling by pneumatic honing & NDE of valve components

- Reverse engineering & manufacture of replacement parts

- Re-establishment of appropriate clearances and restoration of internal alignment

- Engineering evaluation of valve condition and repair

- On-site valve seat replacement

- Sleeve repair

- New valve chests to replace those beyond repair

- Stellite overlay via Plasma Transfer Arc (PTA) welding

MAINTENANCE SERVICES FOR VALVE ACTUATOR HYDRAULIC CYLINDERS

Overhauling of Hydraulic cylinders

- Disassembly and inspection of the internals

- Replacement of the damaged parts

- Assembly with desired assembly CTQs

- Spare part supply by Toshiba

MAINTENANCE SERVICES FOR QCNRVS

Overhauling of QCNRVs

- Disassembly and inspection of the internals

- NDT and contact checks

- Assembly with desired assembly CTQs

MAINTENANCE SERVICES FOR BFP DRIVE TURBINE AND STEAM VALVES

Open, Clean, Close Services (Overhaul)

- Overhauling of BFP drive Turbine

- Opening of the Turbine

- Cleaning, inspection and NDT of the Turbine components

- Re-assembly maintaining the assembly CTQs

- Overhauling of BFP Turbine valves:

- Disassembly, inspection & overhauling of HP & LP stop valves, HP & LP control valves and re-assembly of all the valves.

MAINTENANCE SERVICES FOR BFP AND BP

Overhauling of BFP and BP

- Threading-out of the pump cartridge assembly, stage wise disassembly of the impellers.

- Inspection of all internal components.

- Checking of clearances.

- Re-assembly of all internals, rotary components stage wise with correct clearances.

- Threading-in of repaired cartridge.

- Centering check and setting of radial gaps & axial floats of the cartridge assembly etc.

- Reassembly of seals, bearings, oil pipe lines & other connected lines.

MAINTENANCE SERVICES FOR REDUCTION GEAR AND HYD COUPLING

Overhauling of Reduction Gear

- Disassembly of the gear box. Cleaning, checking of gears. Performing contact checks, backlash check etc. of gear teeth

- Re-assembly of the gear box.

- Alignment of R/G with Turbine & Booster pump

- Overhauling of Hyd coupling

- Dismantling of Hyd coupling

- Cleaning, inspection and re-assembly of the Hyd coupling

AVR & DCS

AVR and DCS services

- Upgradation of the AVR

- Trouble shooting

TOSHIBA JSW SERVICES CAPABILITY

Spare parts supply

- Supply of the spares of Turbine, Generator and steam valves for all the Indian projects for which all the drawings are available with Toshiba JSW under technology transfer commitment.

- For non-Indian projects, Toshiba JSW can supply the spares with the support of Toshiba Energy Systems & Solutions Corporation (TESS) and technology transfer.

- O-OEM spares supply is through reverse engineering and validation by TESS.

- Material equivalent support from TESS in case the materials are not available with Toshiba JSW, applicable both for OEM old machines and O-OEM machines.

- Repair specification / drawings from TESS in case of repair of the parts.

STG Parts Manufacturing & Spare Parts Supply from Toshiba JSW Chennai

Supply of components at competitive price with Japanese Quality for Customers

- Toshiba JSW has complete capabilities to supply self-manufactured or outsourced items as per customer’s needs.

- Efforts are made to procure raw materials locally from Toshiba-approved suppliers.

Parts for STG

- Blades

- Nozzle Diaphragm & Spare parts

- Casings & accessories

- Rotors & accessories

- Control devices & accessories

- Generator & accessories

OOEM Spare parts

OOEM spares supplied by Toshiba JSW

Parts supplied

- Fasteners for Turbine Nozzle

- HP,IP,TG Inlet flange bolts

- IP STG 1 to 5 NOZ DPH

- IP Inlet flange bolts

- Parting plane bolts

- Throttle Valve Assembly

- ST Bolts & Nuts

- Supply of Fan Guard

- Replacement of Brush gear assembly

- High Speed Balancing of LP rotor

- ST Rotor refurbishment & HSB

- Repair of 500 MW LP Rotor

- Repair and HSB of 500 MW LP Rotor

- Repair of 150 MW ST Rotor

- IP STG 1 to 5 NOZ DPH

TA (TECHNICAL ADVISOR) SERVICES

With abundant experience in TG erection and overhauling, Toshiba JSW has developed the TA in the following areas and supporting the global companies

- Turbine disassembly and assembly

- Major steam valves disassembly and assembly

- Generator disassembly and assembly

- Measurement

- AVR

- DCS

- TSI

- Turbine start up

- Generator leak test and start up

- Generator rotor coil inspection

- Generator stator coil inspection

Toshiba JSW offers the following services

- Generator in-situ re-winding

- Generator electrical testing

- All the testing equipment can be shipped to site

- Generator epoxy injection

- Low speed balancing of TG rotors

- In-house Portable machine packed in a container can be shipped to site.

- Expert balancing team

- Reaming and Honing of the coupling holes in case of rotor replacement

- In-house Reaming machine can be dispatched to site

- Experienced specialist

- Steam valves fine mesh removal

- Honing of the Steam valve bushes to maintain the desired clearance

- Honing machine with the experienced specialist can be dispatched to site

ENGINEERING SERVICES (SUPPORTED BY TESS JAPAN)

- Steam path audit

- Risk Based Assessment of Steam Turbine

- Condition assessment

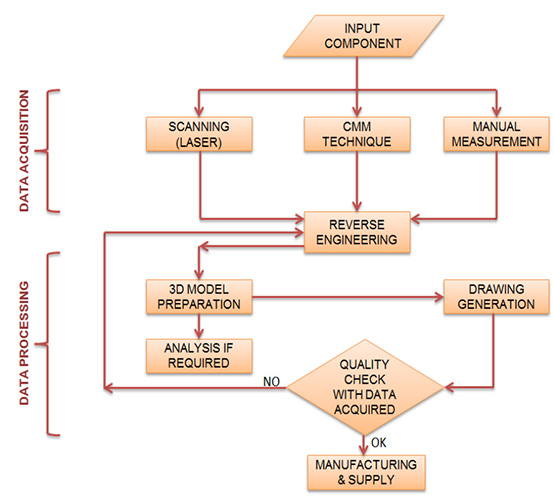

- Reverse Engineering

- Life assessment

- Field balancing

- Trouble shooting

- Recommendation of repair / replace parts

- Provision of spare parts list for maintenance and overhaul

- Reverse Engineering for spares supply

- TESS has services for manufacturing and supplying of parts by 3D scanning measurement.

- Residual Life Assessment

SUMMARY OF TOSHIBA JSW ELECTRICAL CAPABILITIES

- Design, Engineering, Testing, Supply, Erection and Commissioning for Generator Stator Cooling Water System (SCWU), Seal Oil System (SOU), AVR, GACP, Excitation Transformer, Auto Synch and Generator & Transformer Protection System.

- Supplied and Commissioned SOU, SCWU, AVR/GACP and Excitation Transformer for 4 projects of 660 MW and 800 MW capacity in India.

- Supplied and Commissioned Generator & Transformer Protection panels for Anpara U#5 (500 MW) and Harduaganj (660 MW) in India.

- Troubleshooting and System Upgradation (for R&M job). Currently executing an R&M order for replacement of Generator & Transformer Protection Panel of NN2HP Hydro Project in Laos.

ADVANTAGE OF Toshiba JSW

- Global offices hold a good chance to win the bid due to competitive cost of SOU, SCWU, AVR/GCP, Excitation Tx and Tx protection system from India.

- Toshiba JSW complies to quality standards of TESS for all its products and services.