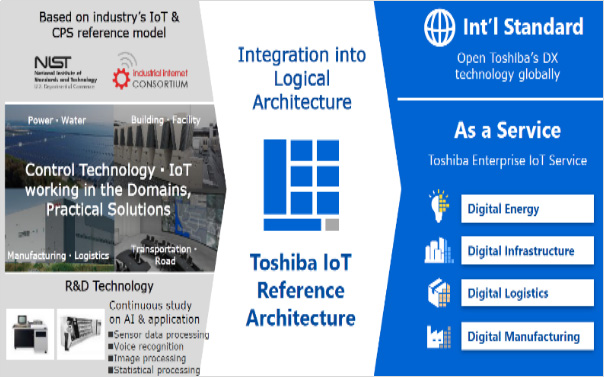

Partnering to provide Enhanced Digital Operations and Maintenance Solutions, Toshiba IoT solutions offer digital solutions in Energy, Infrastructure, Logistics and Manufacturing.

TOSHIBA IoT SOLUTIONS COMPLY WITH INTERNATIONAL STANDARDS

IoT solutions comply to international standards laid by National Institute of Standards and Technology (NIST) and Industrial Internet Consortium (IIC). At Toshiba, we use a 3 Tier architecture with advanced software and services to help clients in improving the reliability, productivity, efficiency and reducing costs.

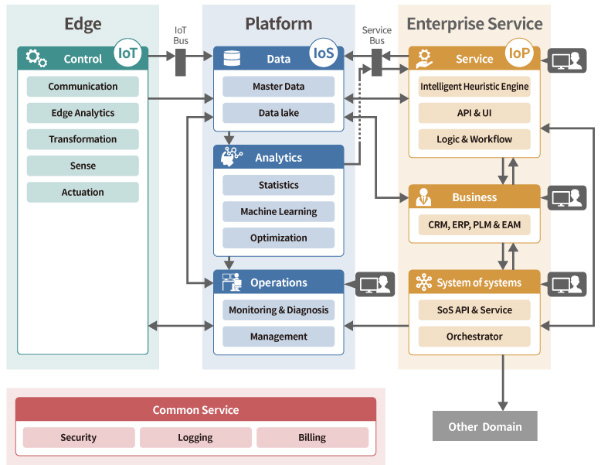

TOSHIBA IoT SOLUTION HAS 3 TIER ARCHITECTURE

Important Feature of Toshiba IoT solutions

- Micro-service (Service Oriented Architecture)

- Hybrid configuration

- Distributed database

- Data link by information model (Ontology)

- Open API for system link (System of Systems)

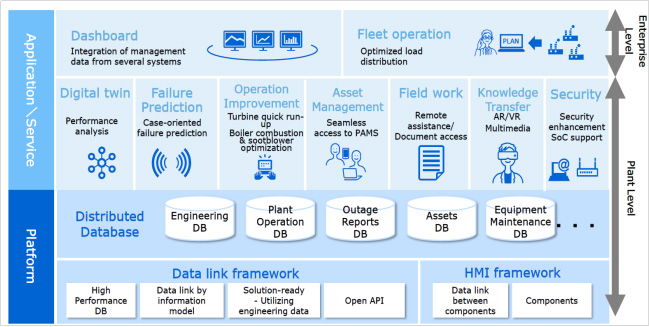

TOTAL LIFE CYCLE SOLUTIONS

EtaPRO VP enables first principles modelling of power cycles to create a virtual model for accurate prediction of thermodynamic performance of power plants. Online real-time monitoring and comparison of actual data with the thermodynamic model predictions help determine the inefficiencies and take corrective actions to equipment/operations accordingly.

ADVANCED PATTERN RECOGNITION (APR)

Build asset specific models for prediction of allowable band of operation for key parameters based on historical plant data. Online real-time monitoring and comparison with the model predicted parameters enables early detection of deviations from normal pattern, an early warning system for potential incipient failures.

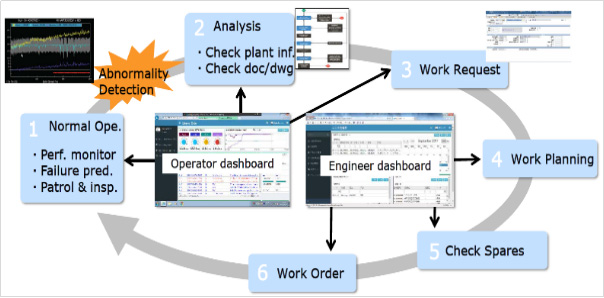

ASSET MANAGEMENT & DASHBOARD

Seamless access to diverse data linking both operation & maintenance which will help in fast, flexible troubleshooting of issues and decrease plant O&M workload.

QUICK RAMP UP & DOWN (QRUD)

Enables to calculate the degradation in turbine life due to thermal stress especially when ramped up / down and predicts the required soak time and ramping rates based on future thermal stress.

BOILER COMBUSTION AND SOOT BLOWING OPTIMIZATION

Plant operation data is collected in real-time and subjected to AI /IoT software analysis, and the results are used to optimize Boiler Combustion and Soot Blowing operation. It helps in improving thermal efficiency of power plants, reducing fuel costs & fewer CO2 emissions.

FIELD WORK & KNOWLEDGE TRANSFER

This involves repair / overhaul of power plants, using 3D modelling, upgradation of plant with upcoming new technologies to monitor the plant efficiently from remote and carry out maintenance by remote online support. It involves enhanced operation and maintenance through AR/VR for field support.